The shoe last is the foundational form that determines a shoe’s shape and fit. It’s an essential component in the footwear manufacturing process, influencing the overall look and feel of the final product. The choice of last is crucial; a well-matched last can elevate a shoe’s design to fashionable heights. While a poorly chosen last can result in an ill-fitting and unattractive shoe.

To create the shoe’s upper, a pattern is crafted to precisely fit the last. This pattern serves as the blueprint for the shoe’s construction. Different types of shoes require unique last shapes to accommodate specific functions and styles. For instance, a running shoe last is designed to provide flexibility and support for athletic activities, while a hiking boot last is built for durability and stability. Ultimately, the last plays a pivotal role in determining the success or failure of a shoe design.

Last Shape, Fit, Performance, and Style

The shoe last is the cornerstone of footwear design, influencing the shape, fit, performance, ergonomics, and overall style of a shoe. It’s the foundational form around which the entire shoe is constructed. Lasts can be crafted from various materials, including injection-molded plastic, carved wood, or cast aluminum.

The last serves as the starting point for any shoe design, shaping the shoe’s structure and determining its suitability for specific activities. Whether you’re lacing up a pair of basketball sneakers, hiking boots, or stylish stilettos, the last plays a critical role in ensuring the shoe’s performance and comfort. A well-chosen last can elevate a shoe’s design, while a poorly selected last can compromise both fit and function.

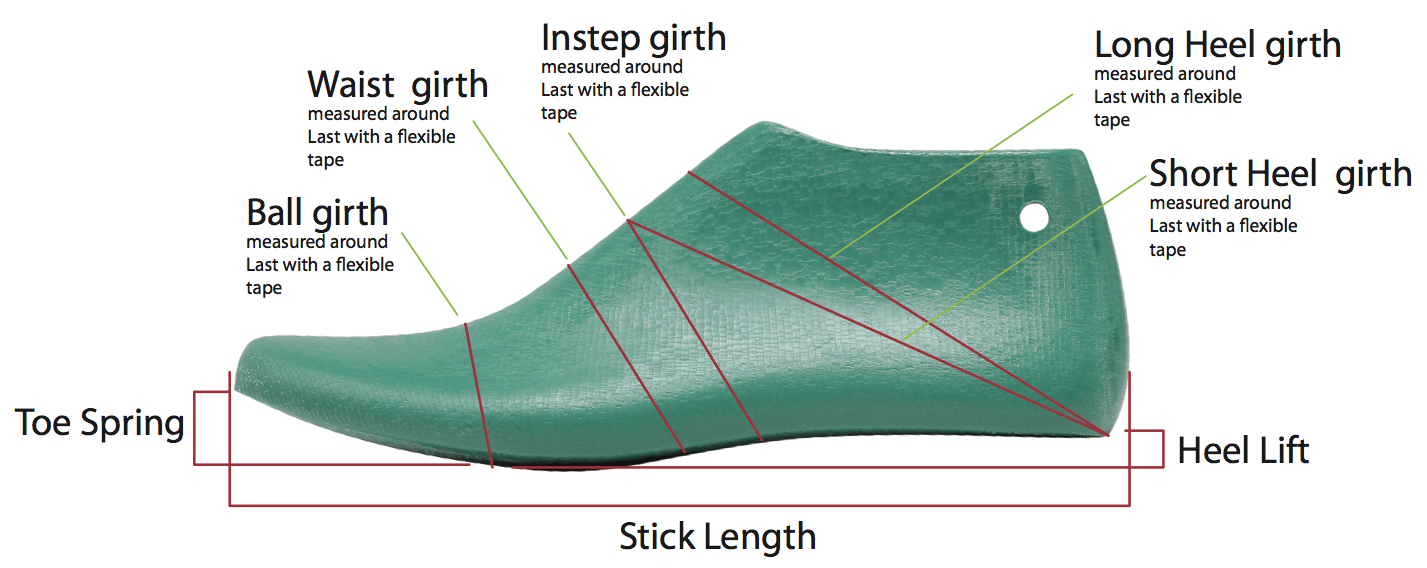

A flexible measuring tape is an indispensable tool for accurately assessing the dimensions of a last. By understanding the specific measurements and terminology associated with lasts, you can gain a deeper appreciation for their role in shaping the fit, comfort, and performance of footwear.

Parts of a Last

A shoe last consists of several key components, including the forepart, instep, cone, back part, waist, and seat. If the last has a hinge, there will be a vent above the hinge point to prevent damage during the shoe removal process.

To aid in shoe construction, lasts often feature tiny bumps that mark specific points, such as the vamp point, toppling point, and counterpoints. These markings serve as reference points for attaching the upper to the last.

It’s important to note that the terminology used for shoe lasts is consistent across different types of footwear, whether it’s men’s sports shoes or women’s fashion shoes.

Footwear Last Measurements

To accurately measure a shoe last, several key dimensions must be considered. The last stick length is determined by measuring the distance between the longest points at the toe and heel. The last ball girth is measured by wrapping a flexible tape around the widest part of the last, typically at the ball of the foot. The last instep girth is measured by passing a flexible tape over the instep of the last. The last waist girth is measured by wrapping a flexible tape around the narrowest part of the last, typically near the ankle. Finally, the last toe spring and heel lift are measured with the back of the last held parallel to the ground.

These measurements are essential for understanding the shape and proportions of a last, which ultimately influence the fit and comfort of the shoe.

Last Bottom Length: Measured with a flexible tape pressed to the surface on the bottom of the last.

Last Ball Width: Measured with a flexible tape across the ball of the last.

Last Instep Width: Measured with a flexible across over the instep of the last.

Last Waist Width: Measured with a flexible tape across the waist of the last.

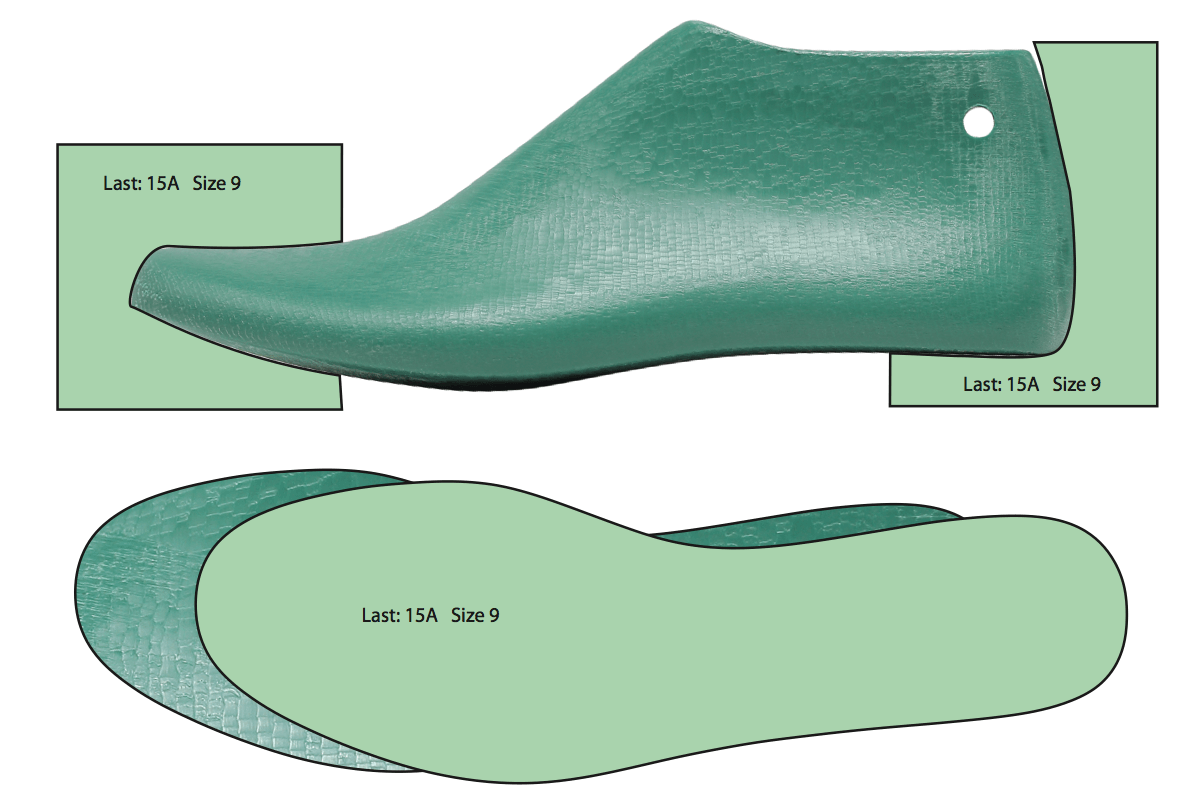

Computer-generated paper templates, known as last gauges, are used to ensure the accuracy of shoe lasts. These gauges are marked with critical dimensions, size, and a code number. They are used to verify the dimensions of sample lasts and subsequently used in production to confirm the consistency of the final product.